You might have seen lasers used to engrave designs on fabric, polymer-based material, or even to remove layers of skin. The cutting power of lasers is well known now. But engraving metals using a laser is not as easy as it sounds. Let’s go a bit deeper into the process!

What is laser engraving?

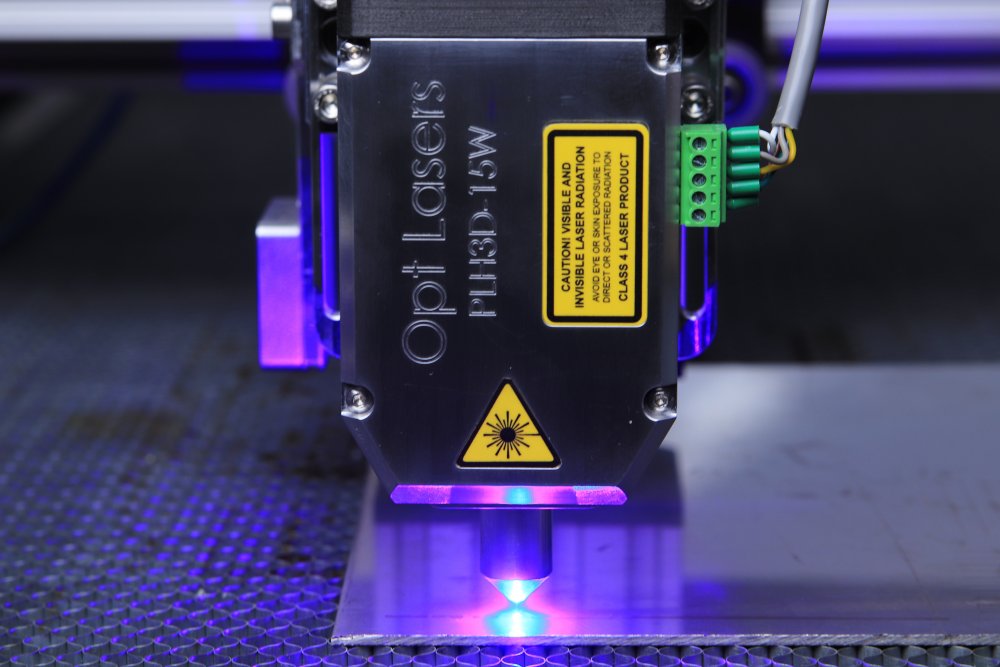

Materials are vaporized during the laser engraving to create deep, lasting markings. By scraping away layers of the material’s surface, the laser beam behaves like a chisel to make marks on the surface. The laser delivers concentrated amounts of energy to specific locations to produce the intense heat necessary for vaporization.

Metal workpieces that will be subjected to different kinds of wear or surface treatments are frequently engraved using laser engraving technology. Steel and aluminum can be used for metal engraving (including anodized and die-casting aluminum). The capacity of this method to engrave 2D codes with reasonable readability rates even after post-processing treatments is by far its most remarkable characteristic.

The most complicated traceability difficulties can be addressed with these treatments, which can involve shot blasting, e-coating, and heat treatments. However, laser etching is typically chosen because it is a quick process that doesn’t rely as largely on ablation when engraving the toughest identification. A wider range of materials, including steel, aluminum, anodized aluminum, lead, magnesium, and zinc, can be etched with a laser.

Additionally, a novel technique for marking metals like stainless steel is known as laser annealing. Laser engraving sublimates the material surface to produce deep fissures, in contrast to laser etching which melts the material surface to change its roughness. This indicates that the surface quickly absorbs enough energy to transform from a solid to a gas without ever becoming a liquid. The laser engraving system must produce enough energy to enable the material’s surface to reach its vaporization temperature within milliseconds to achieve sublimation.

Laser engravers are pretty potent tools, especially in light of the high temperatures needed for sublimation. When materials get to this temperature, they evaporate and turn into fumes. As a result, a laser system should always be purchased with an air knife to protect the laser’s lens and a fume extraction system to safeguard the working environment. Because they provide a wavelength that works well with metals, fiber lasers are the best engraving equipment for this.

What are the parts of a laser engraver?

The machine host, the laser generator, the laser head, the numerical control system, the operation console, the laser-regulated power supply, the chiller, the gas cylinder, the air compressor, the gas storage tank, the cooling dryer, the filter, the exhaust dust collector, and the slag discharge machine, are the main components of the laser engraving machine. The function of each element is as follows:

- Operation Console: This console controls the entire engraving operation.

- Machine host: It is a fiber laser cutting machine component responsible for the mechanical movement of the X, Y, and Z axes.

- Laser generator: It is a crucial part of the laser cutting device. And it produces a laser beam with a high energy density, which can cut materials.

- Servo System: It is a form of automatic control that enables the output-controlled volume of the object, such as position, orientation, and status, to adapt to changes in the input target. Additionally, it can improve the precision of both location and control speed.

- CNC components: It is utilized to control the machine’s X, Y, and Z axes’ motion as well as the laser’s output power.

- Regulated supply system of power: It connects the power supply system, the CNC machine tool, and the laser generator in order to avoid interference with the electricity grid from outside sources.

- Laser head: It is a laser output device with a focus tracking system, a nozzle, and a focusing lens. It completes processing on various materials using the predetermined cutting trajectory. Furthermore, the height of the laser cutting head must be changed and controlled for multiple materials, thicknesses, and cutting techniques.

- Cooling unit: It is a cooling mechanism for the laser cutting machine that can swiftly and effectively cool the laser generator while maintaining the laser generator’s normal operation. Additionally, it can efficiently prevent the lens from becoming too hot and causing distortion or bursting by cooling the machine tool’s external light path mirror and focus mirror.

- Gas cylinder: It has a gas cylinder for the laser cutter’s working medium in addition to a gas cylinder for the cutting head’s auxiliary gas and laser-oscillated industrial gas.

- Air compressor: It is to store, and supplies compressed air.

- Dust collector: It filters and extracts dust produced during processing to ensure exhaust emissions meet environmental protection regulations.

- Slag discharge machine: It is employed to eliminate corners and processing-generated scraps.

5 Best laser engravers for metals

- Ortur Laser Master 2 Pro: The Laser Master 2 Pro, the newest metal laser engraving device from Ortur, is a recently upgraded device with some amazing capabilities. Despite the fact that it seems unlikely that a non-CO2 or fiber laser could carve on metal, various tests have been carried out and have successfully marked metal with logos and other small features. Operational safety has been prioritized with this device; it includes a flame detection feature, an emergency stop, and an updated voltage system. It automatically stops if the laser is intervened or touched in any manner.

It’s undoubtedly among the greatest metal laser marking devices available. For metal engravers, accuracy is the most critical factor, and this machine definitely delivers on that front. It has the most recent OLM-PRO-V10 motherboard, ensuring smooth, delicate engraving while offering highly precise and quick engraving speed. Additionally, it utilizes the potent Ortur Laser 1.5 firmware. The motion algorithm is improved, and the movement speed is increased by up to 10,000 mm/mm. It makes use of a second-generation FAC laser type, which has a focal point as small as 0.08*0.15mm and produces strong, fluid metal engraving.

- Atomstack X7 Pro: The Atomstack X7 Pro is a more expensive desktop laser engraver. Its potent 10W laser easily slices through 15mm acrylic and wood up to 20mm thick. With this ability, it is also possible to mark metals, such as with light signatures or logos, or to add barcodes or serial numbers to products to increase product traceability. Even though many hobbyist metal laser engraving projects are typically on the smaller side, the wide 410 × 400 mm engraving area is more than ample. However, it can expand to 850 x 410 mm with the X7 Pro extension kit.

With an ergonomic touchscreen, offline engraving options for workshops without WiFi, and an improved laser with a more consistent beam and a compressed laser spot (0.06mm) for sharper details, it is simple to operate.

- xTool D1 10W: The processing precision of the xTool D1 Pro is astonishingly high, reaching 0.01 mm thanks to its industrial-grade structural design. Whatever the engraving or cutting task, the xTool D1 Pro always displays the best details due to its 0.08*0.06mm ultra-fine compressed laser spot. With compressed spot technology, a smaller laser focus (from 0.15*0.15mm to 0.08*0.06mm) produces flawless details.

This device combines two laser beams into a single spot using cutting-edge twin laser technology. Under the same electric power, the compressed spot has greater power, cutting ability, faster speed, and better results. A single laser 15W laser cutting device has the same power as the 10W dual laser xTool D1.

- Snapmaker 2.0 3-in-1: The Snapmaker 2.0 Modular 3-in-1 is the most unusual laser engraver since, in addition to being a laser engraver, it is also a 3D printer and a CNC carving machine. Along with the laser engraving component, this machine includes a superb autofocus capability that employs the best laser height automatically without requiring you to continuously test for the focal point. We advise you to get the high-power laser add-on for engraving tougher materials because the ordinary 1.6W laser tool head has trouble engraving metal, even though this maker online has managed to make it work.

Snapmaker is perfect for beginners because of its emphasis on simplicity and accessibility. Their auto-calibrating Snapmaker Luban software and the sophisticated and intelligent Snapmaker firmware measure the depth and area of the material. The software’s Snapmaker Luban immediately uploads a photo of the material as a canvas using the outstanding camera capture feature. A photograph can be imported, edited right on the canvas, and then engraved with only one click.

- LYXC Hybrid Metal Laser Cutter & Engraver: The LYXC hybrid laser cutter is well worth a look if you’re searching for an industrial metal laser engraver that can produce big volumes while keeping good quality. This hybrid machine can do various tasks because it features a 180W RECI W8 head for laser cutting and an 80W RECI W2 head for laser engraving. This extremely strong laser cutter and engraver can etch stainless steel sheets up to 1.5 inches thick. A wide range of non-metal materials, such as wood, Plexiglas, bamboo, crystal, leather, and ceramics, can also be worked with it. These can be cut up to 1.8mm, as well as carbon steel sheets.

Conclusion

Laser engravers are used to cut objects and draw designs on solid objects. However, metals are tougher objects and therefore require powerful lasers and components capable of supporting the laser in the metal engraving process. Metal engraving is used for carving information, designs, or logos on metals. Like laser engraving, 3D printing is also a CNC-related process used for rapid manufacturing. If you would like to prepare the G-code for your laser machine, you can use the online slicer of SelfCAD to do the job.